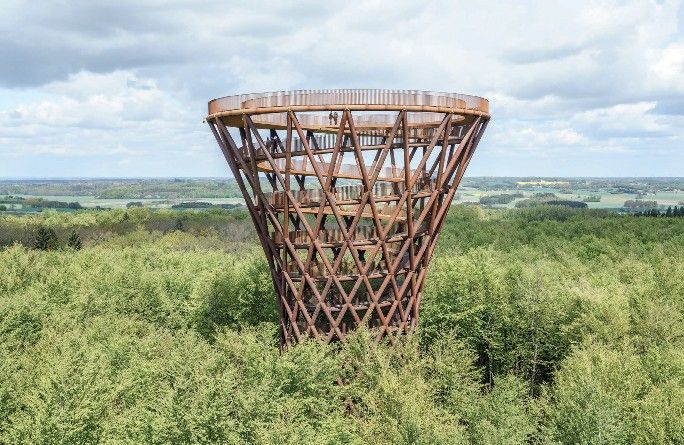

Laudation: The beautiful tower enables special experiences tone in tone with nature. Its mathematical hyperbolic shape, optimised by parametric design, employs eco-friendly weathering steel tubes of evidently appropriate trunk dimensions. What a natural and lovely combination of steel and timber.

Project owner | Camp Adventure | Kasper Larsen |

| Location | Skovtårnsvej 1, 4683 Rønnede, DK | |

| Architect | EFFEKT | Mikkel Bøgh |

| Structural Engineer | Arup | Claus Jensen |

| Steel Contractor | JVP STEEL POLAND | Jan V. Stjernebjerg |

| General Contractor | Levi Jensen | Levi Jensen |

| Date of Completion | March 2019 | |

| Steel Tonnage | 650 tons |

© Camp Adventure, EFFEKT Architects and COAST Studio

© Camp Adventure, EFFEKT Architects and COAST Studio

Forests in rural Southern Zealand one hour from Copenhagen are the setting for one of the most featured Danish attraction in the media.

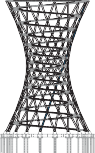

The 45 meter high Forest Tower was designed with the ambition to create an aesthetically beautiful building and a unique experience with nature in focus. The shape is inextricably linked to the hourglass shape, where the bottom and top are maximised, whilst the middle is laced hyperbolically. This narrowing in the middle of the construction is important for the experience in the Forest Tower, as you get very close to three beautiful beech trees, which grow in the middle of the structure. The rotation is created by the vertical steel tubes rotating 120 degrees. As you move up through the tower, you also experience that the distance between the ramps changes until you reach the viewing platform 140 meters above sea level, where you have a 360 degree view of the landscape.

© Camp Adventure, EFFEKT Architects and COAST Studio

© Camp Adventure, EFFEKT Architects and COAST Studio

The hyperboloid diagrid form creates an efficient structure composed of steel tubes. The tower sits on concrete cones transferring the column loads to a concrete ring beam that sits on driven precast concrete piles. A spiral steel ring beam supports the walkway and stabilises the diagrid. Complex finite element analysis determined the right stiffness between the offset and the column connection. A parametric workflow allowed time to be spent where it truly mattered, concentrating on the details of the analysis, vibrations and how to create connections that facilitated the tower’s assembly.

© Camp Adventure, EFFEKT Architects and COAST Studio

© Arup

The diagrid structure was divided into three 15 m sections of 18 elements each fitting on trucks. An erection tower was placed inside to access connections for site welding. The walkway was erected from the bottom with a small crane inside and from the top with a crane lifting the elements inside. The segments were joined to the diagrid with bolted connections with prestressed bolts.

© Arup

The hyperbolic shape and the parametric workflow ensure an effective material use. Weathering steel minimises maintenance and avoids painting. The decking is made of local PEFC certified oak.

| << previous project | start page | next project >> |